AirGap isolation

This process is similar to double glazing. Double glazing used to insulate the interior of a house to keep it warm by Insulating the interior, the house isolated from external noise and vibration. When triple glazing used, the results are even better. And in the same manner, audio cable isolation is necessary to reduce the effects of external Vibrations.

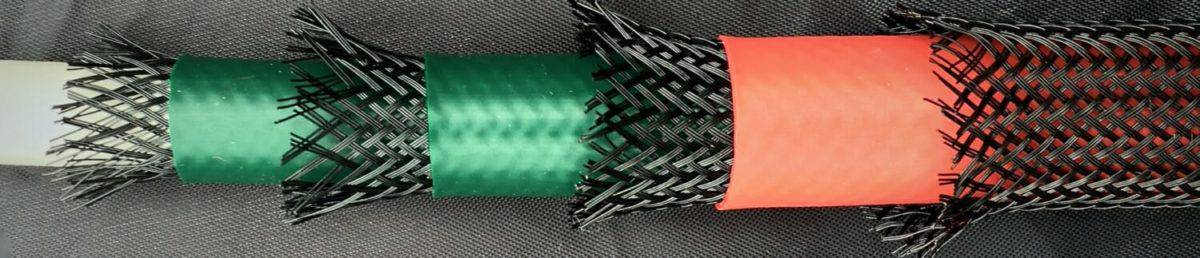

The picture shows a white power cord running from left to right. Over the power cord, runs a layer of black material called CanuFlex PE-HB. This material has a beautiful ‘mesh’ and, used to trap pockets of air. And is very effective in doing so!

CanuFlex

The CanuFlex PE-HB covered with a green sheathing material DeRay-PBFSP. The article heated to a predetermined temperature. As the DeRay-PBSFB contracts, the air is trapped, and insulation is formed around the cable. A second layer is added when the process is repeated. A third layer can be added if necessary.

he ‘AirGap’ isolation process makes an audio cable perform better. This is because the cable is isolated from external vibration and interference.

Composition

- Perkune audiophile ‘AirGap’ insulation has over 720 pockets of trapped air per square inch. These pockets of trapped air are in the material which runs around the entire length of the cable.

- The Perkune audiophile power cord has a diameter of 9.0 mm.

- After three levels of isolation, the power cord diameter increased from 9.0 mm to 15.0 mm in Diameter.

- An increase of 40%, giving excellent results in performance.

- The Power cord is still flexible and easy to use.

Packing

The Power cord insulation is from top to bottom. And, padding also made to the termination screws. And, gives the ultimate connection and reducing the effects of mechanical and electrical vibration. WoolRock packing is used and is a high-grade professional quality.

Interconnect cables

Working with interconnecting cables, the Canuflex PE-HB covers all connections. And, ‘tip to tip’ coverage which ensures perfect isolation from external interference. The WoolRock, packed into the outer housing of the XLR connector plugs.

Loudspeaker cables

When applied to a loudspeaker cable, the Canuflex PE-HB covers connections. And, giving ‘tip to tip’ coverage, which ensures perfect isolation from the effects of mechanical and electrical vibration.

Conclusion

The ‘AirGap’ isolation process, can be applied to any cable where isolation is required. The performance is greatly improved by using these techniques regardless of the system price.

I have been testing for months and have excellent feedback from my colleagues and customers. The results inspired me to improve the range using the ‘AirGap’ isolation and Anti-vibration technique. A person is now able to hear more of the musical presentation than ever before, which in itself is inspiring!

If you have enjoyed reading the ‘AirGap isolation’, please share with friends – thank you.

Perkune – Best budget Audiophile Cables